SCR SOUTHWIRE CONTINUOUS ROD

SYSTEMS

| SCR system of this company was imported from US Southwire

Co. in a whole plant equipment, with annual production of copper rods over 8mm exceeding 70,000

tons. The equipments underwent many upgrades and self-innovations and have reached the goal of

automated production manufacturing process. |

|

|

ELECTROLYTIC COPPER CATHODES

This company only uses the super and highly purified electrolytic copper cathodes with grades above

the LME Grade A.

AUTOMATIC CONTROL SYSTEM

This equipment is of the latest model of centralized surveillance system and adopts the

digitization, computerization, automation for all functionalities. It not only stabilizes the

production operation but also maintains copper rod’s high quality throughout the process.

|

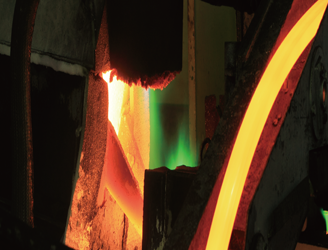

MELTING FURNACE

It adopts the vertical furnace with high efficiency in heat-burning utilization, homogeneous copper

water dissolution, low pollution and low MTBF. Therefore it is an advanced melting device.

|

|

CASTING

It has the automated casting control. In conjunction with comprehensive cooling system, it can

produce the high density, non-pore and bar-shaped crystalline copper cast rod so as to manufacture

copper rod with the best quality there is.

NON-TWIST ROLLING MILL

We adopted the Non-twist rolling mill facility of Morgan, USA, to ensure the production of copper

rod characterized with low oxidized film, high elongation rate and smooth surface.

|

|

SCR 8.0m/m

Each pallet is coiled with 4~5 tons of 8 mm copper rod without plugs which can cut down the number

of connection made during downstream manufacturing process and ultimately streamline the overall

operation.

|

UPCAST SYSTEM OF OXYGEN FREE COPPER

ROD

The upcast system for oxygen free copper rod which has undergone our self-researched enhancement

processes can minimize oxygen content to the level below 2ppm. This product line primarily supplies

the needs from our parent company, the electronic wiring clients and related industries for

manufacturing purposes: LAN cables, fine enameled wire, flat enameled wire, thin coaxial etc. It can

also be manufactured into resistor, capacitor and inductor, etc, the so called terminal

manufacturing wires. Each pallet is coiled with 3~4 tons 8mm copper rod without pre-connection; and

we also accept client’s custom-made orders.

COPPER WIRE

We provide our clients with 2.6 mm per frame, approximately 1660 kg bare copper wires without

connectors and allow our clients save more manpower in the downstream manufacturing process and

raise the level of efficiency.

|

|

|

|